Event Description

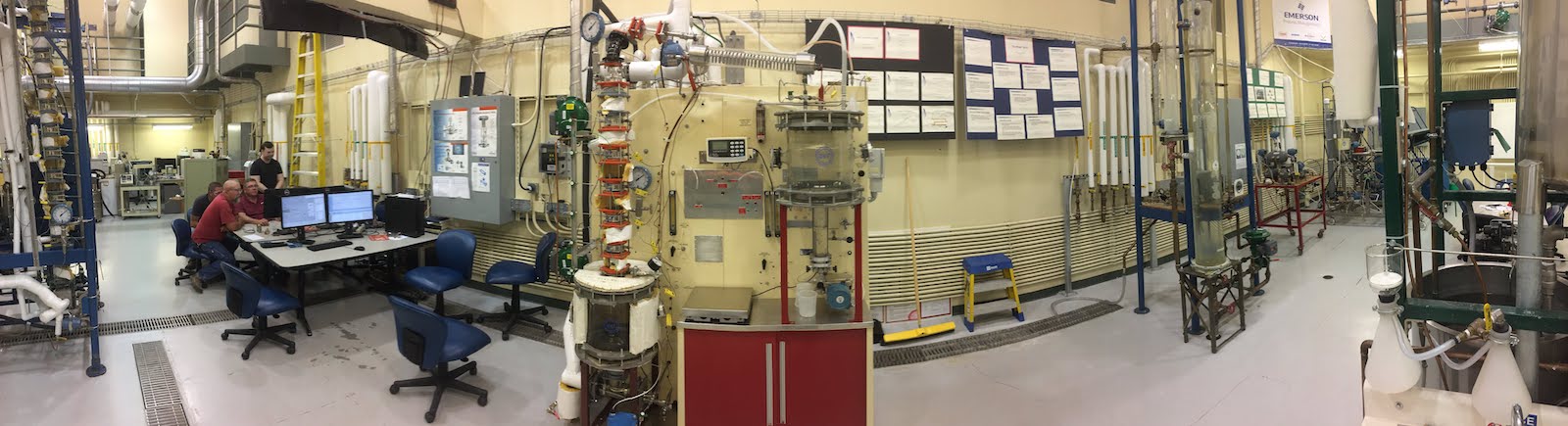

This course will provide industrial personnel with a better understanding of all elements in a PID control loop including the sensor, actuator, process, and controller. Participants will gain hands-on experience operating and tuning loops using pilot-scale equipment. Several different tuning methods and control structures will be explored.

Benefits

Combining lecture and demonstrations, participants will gain the ability to:

- Define and understand concepts and parameters of PID control

- Evaluate the stability of different open and closed loop processes

- Identify and troubleshoot common control loop problems

- Tune control loops using different methods

- Apply and understand the advantages of cascade control loops over single PID control

Intended Audience

Plant operators, maintenance personnel, and engineers of any experience level who use or maintain control equipment and/or DCS systems. Participants will receive a certificate of completion which may be used to document professional development hours.

Registration

Tuition is $600. Tuition Reimbursement: The Nebraska Ethanol Board is offering a tuition reimbursement of $300 per person upon completion for employees of qualifying ethanol plants located in Nebraska. Registration and reimbursement funds are limited to 16 qualifying registrants.

Note: Refunds will not be offered for canceled registrations but substitutions are allowed at the discretion of the University of Nebraska-Lincoln.

Next Class TBD

Instructors

Dr. Hunter Flodman, Associate Professor of Practice, University of Nebraska Chemical & Biomolecular Engineering

Scott Harmeier, Process Optimization Manager, Archer Daniels Midland Company