Description:

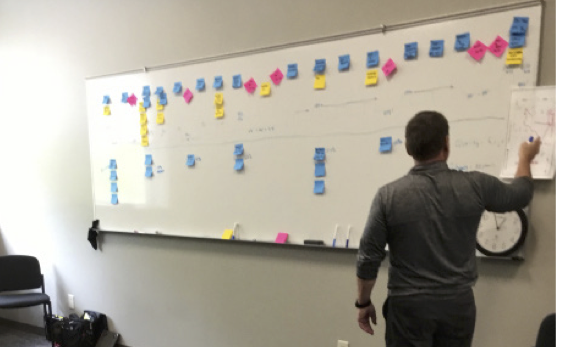

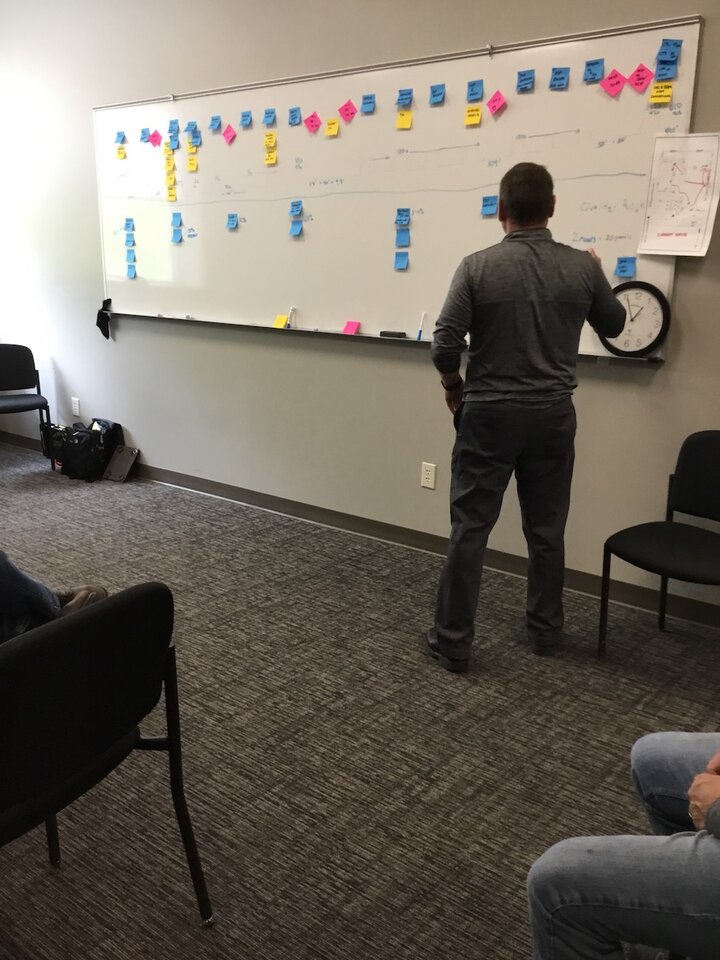

Value Stream Mapping helps to define your manufacturing process, identify key deliverables and design improvements in the factory layout and how workers and materials are best utilized. Using a flowchart method, VSM is a way of diagramming and documenting workflows, informing material usage schedules, and to remove nonessential activities that create waste while maintaining the manufacturing process. VSM is an essential element of Lean manufacturing.

Overview

Introduction to Value Stream Mapping

Diagramming processes

- Phase 1: Define Product/Service Family

- Phase 2: Document Current State

- Phase 3: Define Future State

- Phase 4: Create an Implementation Plan

Target Audience

Company leadership, supervisors, quality team members, and key line personnel.

Delivery Method:

Members of the production team collaborate in a 2-day session to map out current processes, design a future state and create an implementation plan.

Value Stream Mapping suggests best practices to set up a plant in order to reduce time frames and reduce energy usage.

Learning Outcomes

- Gain an overview of Lean concepts and principles

- Gain an in-depth understanding of your current work systems and the related barriers to delivering value

- Design a future state that enables outstanding performance

- Develop an action plan to achieve the future state and lay the foundation for continued improvement