2022

"We identified material requirement planning as an area for further investment, but we were looking for funding to make those improvements. Connecting us to TAAC and guiding us through the grant process was transformative for us and helped position us much better for the future. We’ve appreciated the various help we’ve received with marketing, sales, and strategy development from the Nebraska MEP."

Gary Bales, President

Webinar & follow-up assistance leads to investment in company’s growth

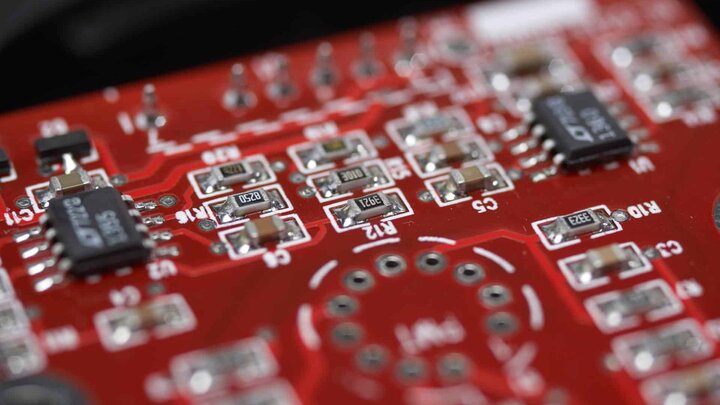

International Sensor Systems, Inc. (ISSI) (Now AURORA BOARDWORKS) of Aurora, Nebraska, is a manufacturer of custom electronic assemblies for industrial, medical, military, agriculture and oil and gas applications. ISSI’s mission is to supply superior product quality and excellent customer service specifically to the industrial, military, medical, agricultural, and oil & gas marketplaces. Their dedicated staff of approximately 30 employees uses advanced technology to consistently meet and exceed their customers' expectations.

The Challenge

Gary Bales, President of ISSI, was looking for funding to help modernize their systems to facilitate growth and improve profitability. attended a webinar that was sponsored by the Nebraska Manufacturing Extension Partnership (MEP), part of the MEP National Network™, which discussed services offered by the Mid-America Trade Adjustment Assistance Center (TAAC). TAAC helps companies take advantage of the Trade Adjustment Assistance for Firms (TAAF) program through the US Department of Commerce. This program assists U.S. manufacturers in becoming more competitive by offering cost share matching funds that can be used to pay a portion of qualifying expenses.

By attending this webinar and getting connected with TAAC through the Nebraska MEP, the company was able to achieve this goal.

MEP's Role

The Nebraska MEP connected ISSI with consultants from TAAC. A series of phone conversations led to detailed data collections to help guide and lead ISSI through the grant qualification process. This process led to ISSI being qualified to receive a grant that allowed ISSI to begin their process of improving profitability and becoming a more scalable company.

Using the matching dollars from the grant, along with money from ISSI, the company has been able to invest in their employees’ skills. The company hosted a 3-day on-site consulting and training session where 12 employees received training on various aspects of their materials requirement planning (MRP) system which, in turn, led to a more efficient use of the system. This training led to better planning and purchasing activities and processes for ISSI.

Additionally, ISSI sent 2 employees to training on IPC J-STD-001, which is the requirements for soldered electrical and electronic assemblies. This is the preeminent standard for electronics assembly manufacturing worldwide, used in the final inspection of product.

Results

| $13,000 invested in MRP training for employees, which led to MRP enhancements |

| $4,500 invested in training 2 staff to meet IPC J-STD-001 requirements for electrical soldering |

| Received a grant that offered a 3-to-1 match to invest in MRP systems & other improvement projects |