Register for Kearney, March 10 - Lincoln, April 26Lean 101 Simulation Workshop

SCOTTSBLUFF 4/21-Register by April 14 at 📞 308.635.6701 BRIDGEPORT 4/22-Register by April 14 at 📞 308.635.6701 Register-LINCOLN 4/26

Description

Lean 101 is an industry-leading certification program that provides individuals and companies with a comprehensive guide for professional and workforce development that is in line with Manufacturing Industry standards. It involves innovative ways of thinking with real hands-on applications, leading to improved results. Lean is a smart way to do business that can result in many benefits for companies that practice its components.

Among the benefits:

- Identify wastes and improve efficiency

- Can standardize process and practices in your organization

- Helps demonstrate to customers, suppliers, and others that your organization is using best practices to improve the experience of working with your firm

- Can result in happier and more content employees

Target Audience:

Company leadership, supervisors, and key line personnel.

Delivery Method:

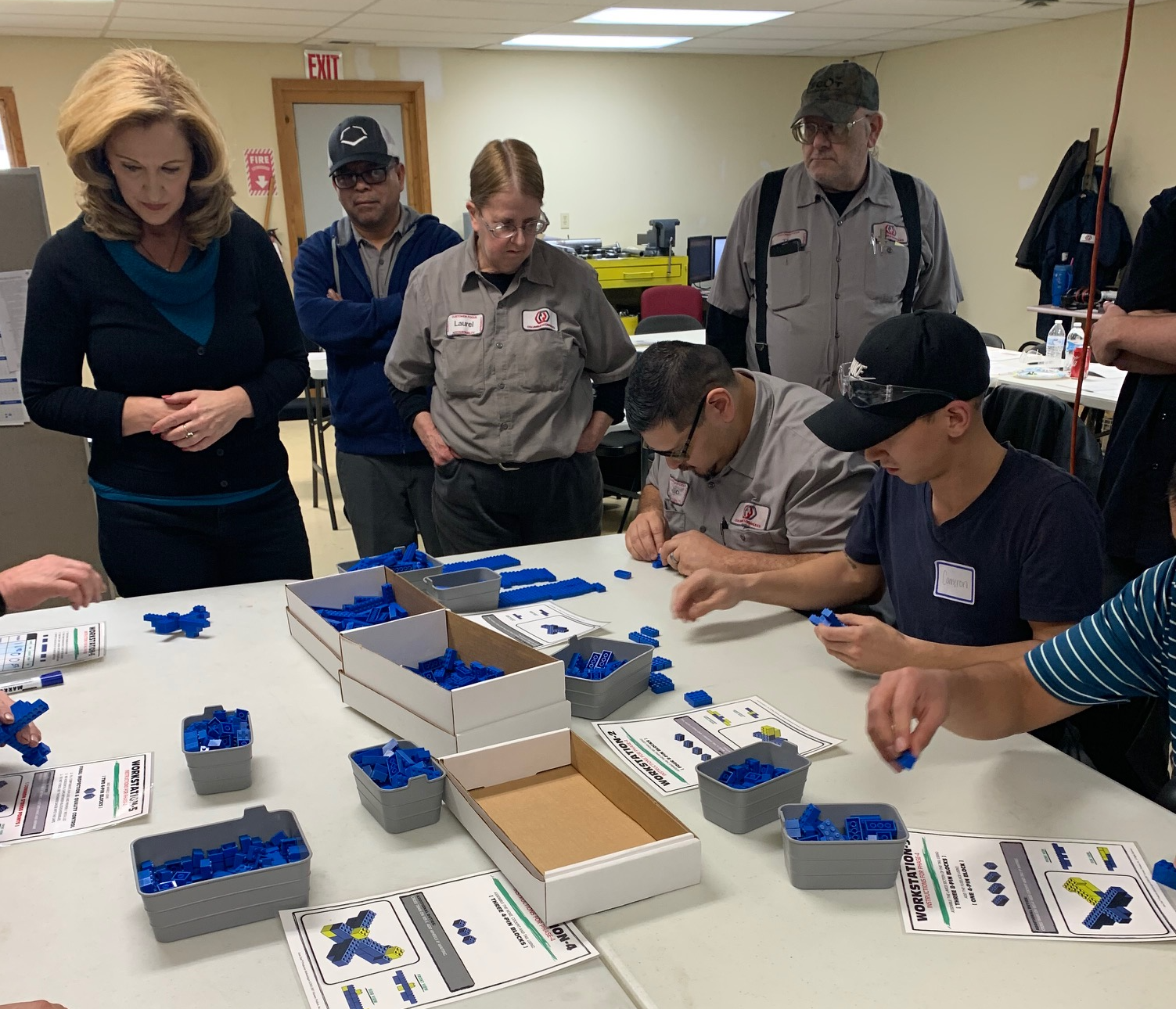

1-day class using a Lego airplane simulation process to help the understanding of these principles:

- Excellent method to break down paradigms

- Start with a key group that needs to have support from ownership \ management

- Transforms current state to owners of the process and shared responsibility for their key areas

- Visual, hands-on demonstration of how changes can improve productivity

- Raises awareness level of what to look for in waste and process improvements Helps to break down employees’ natural resistance to change

- Employees involved in the simulation understand why lean production methodologies are necessary

- Removal of fears regarding change while encouraging them to identify non-value added activity

Participants operate six simulated workstations along the assembly line in their imaginary aircraft plant. The four-phase simulation begins with participants producing airplanes using a traditional plant layout. In phases two and three, they redesign their work area into a cellular layout and learn to utilize one-piece workflow with a pull system. In the final phase, they experience the concepts of a flexible workforce and load leveling. Supplier problems, labor skills, deadlines, quality control, and other real-life situations have been incorporated into each phase of the simulation. Each phase includes time for comments and discussion.

Learning outcomes:

Teaches the following advanced manufacturing practices:

- The benefits of cellular manufacturing over traditional plant layouts

- The effects of rapid throughput with traditional manufacturing

- Work-in-progress as a manageable asset

- Inventory risks

- Independent cross training

- One-piece workflow with a pull system

Delivery Method:

Lecture/Group participation. Participants will receive training a full training manual; a laminated card with key points and certification from the Nebraska MEP and the University of Nebraska-Lincoln.

Registration

Kearney

March 10, 2022

9:00 a.m. to 3:00 p.m.

Central Community College

1215 30th Avenue

Kearney NE 68845

Cost is $200 per person and includes lunch and snacks.

Capacity limited to 20 persons

Lincoln

April 26, 2022

9:00 a.m. to 3:00 p.m.

237 So. 70th Suite 219, Lincoln, NE 68510

Cost is $200 per person and includes lunch and snacks.

Capacity limited to 15 persons

Omaha-cancelled

Cost is $200 per person and includes lunch and snacks.

Capacity limited to 20 persons

Scottsbluff

Western Community College's Operational Excellence Series Training for manufacturers, food and ag processors, and the businesses and organizations who serve them.

Sponsored by Western Nebraska Community College

April 21, 2022

9:30 a.m. to 3:30 p.m.

John H. Harms Center

2620 College Park, Scottsbluff, NE 69361

Cost is $250 per person and includes lunch and snacks.

Capacity limited to 15 persons

Register by April 14 at 📞 308.635.6701

Bridgeport

Western Community College's Operational Excellence Series Training for manufacturers, food and ag processors, and the businesses and organizations who serve them.

Sponsored by Western Nebraska Community College

April 22, 2022

9:30 a.m. to 3:30 p.m.

Praire Winds Community Center

428 N Main St, Bridgeport, NE 69336

Cost is $250 per person and includes lunch and snacks.

Capacity limited to 15 persons

Register by April 14 at 📞 308.635.6701